Products

RODUCTS

PBEKA-PLAST Lining Plate

The Bekaplast? system used by Steuler Anlagenbau in flue gas scrubbers since 1999 sets new

standards.

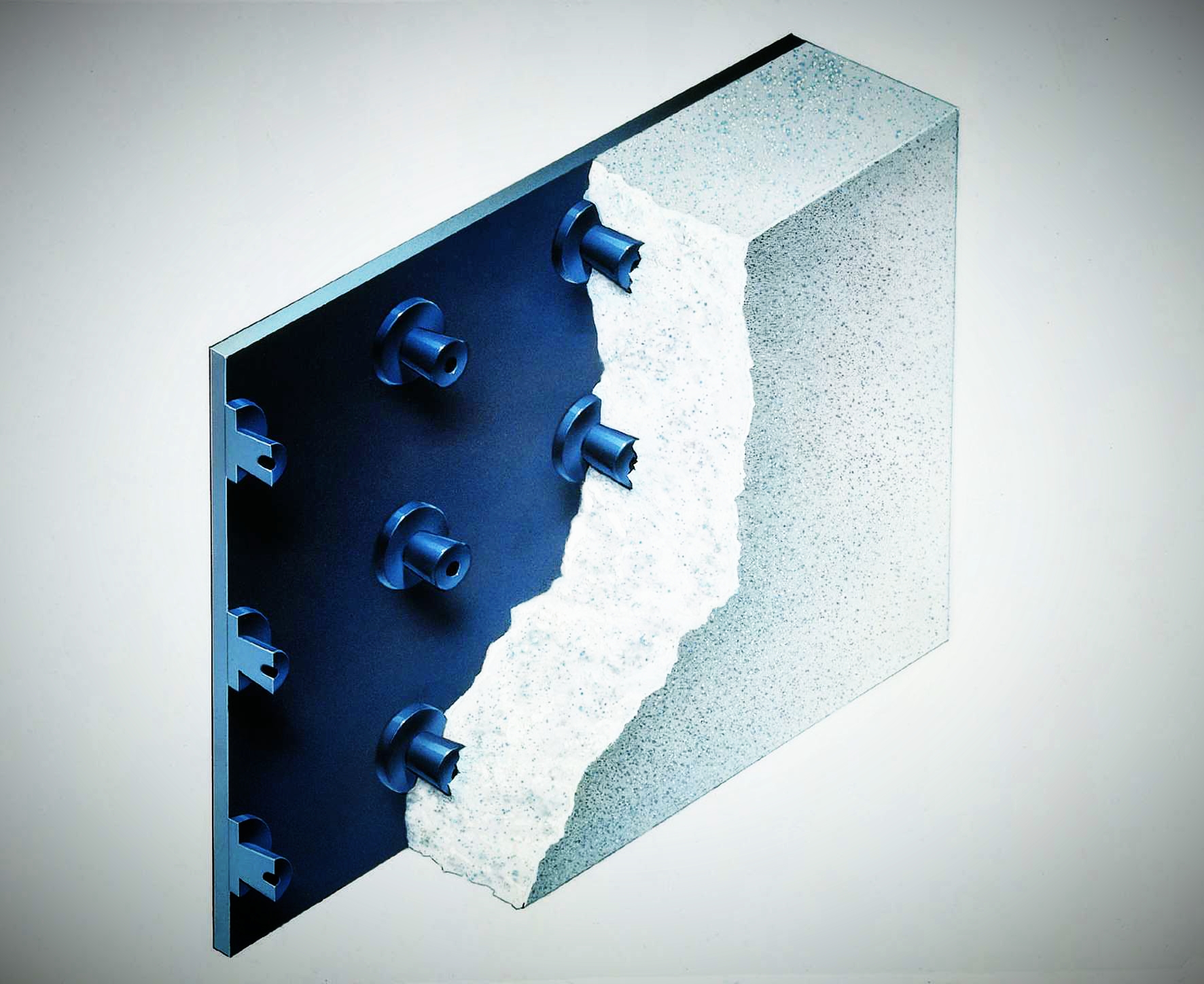

Bekaplast? consists of large-scale thermoplastic sheets with a thickness of 5 to 8 mm. Thanks to its outstanding chemical, thermal and mechanical resistance properties as well as its particularly good resistance to abrasion and excellent anti-adhesive properties,polypropylene is the ideal material for mechanically anchored corrosion-protection linings in concrete scrubber constructions.

Conical knobs have been welded onto the back of the sheet. These large knobs create an insoluble mechanical bond between plastic lining and t concrete structure. The service life of the Bekaplast?

lining is far superior to that of other known lining materials, such as rubber or artificial resins.

Damage from media absorption, the formation of deposits or chemical alterations in the surface can

be virtually ruled out.

Because the nozzle levels, pipes, droplet separators and screening baskets can also be made out

of polypropylene, only one material is used throughout the entire flue gas scrubber.

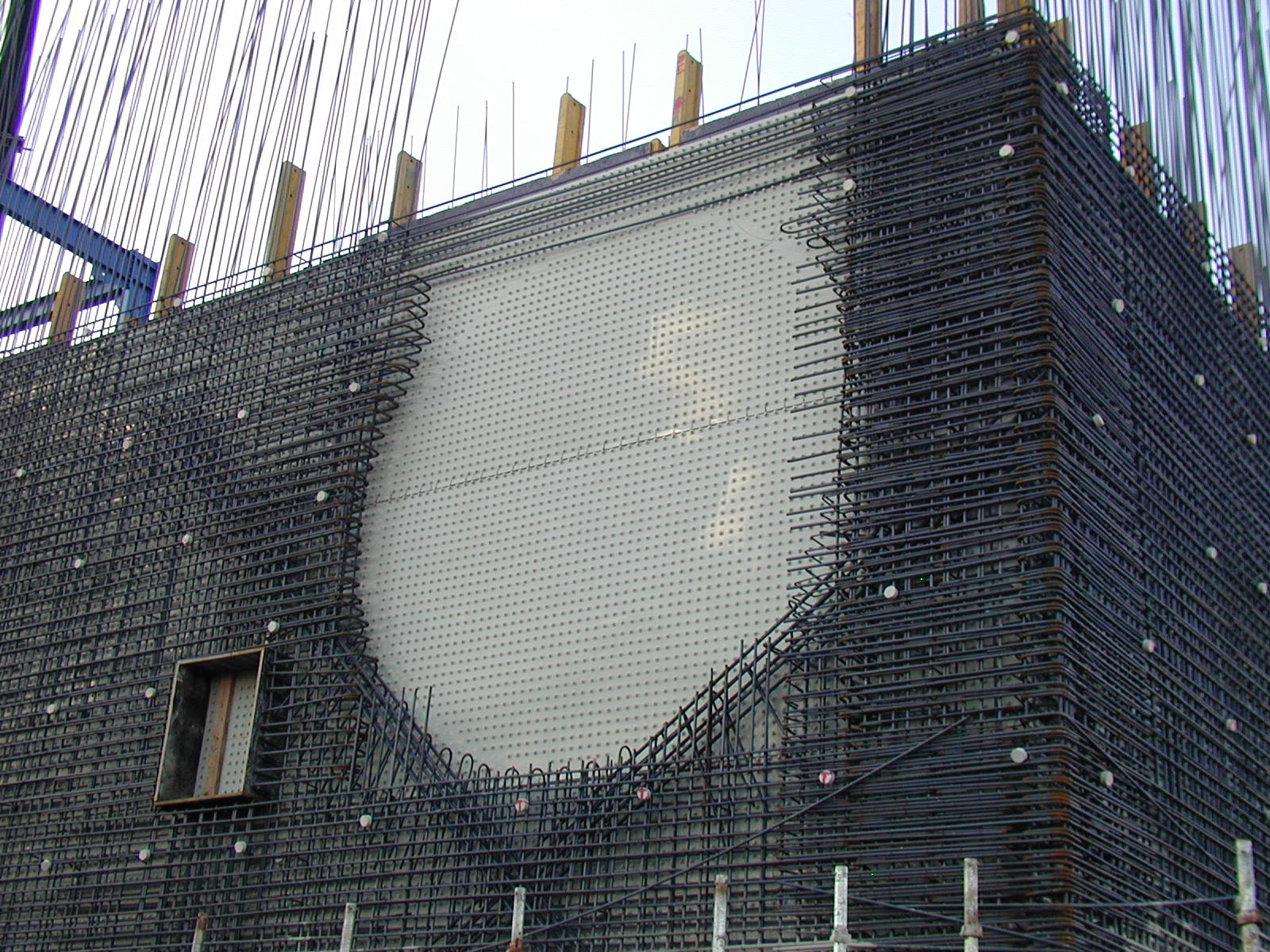

Because the concrete structure and the lining can be constructed in just one work step this method

offers great time advantages. The entire construction can be quickly commissioned at full load.There

is no longer any need for complicated pre-treatment processes, such as those required when retro-

fitting structures with other corrosion protection linings, nor are there any hazardous chemicals re-

quiring precautionary health measures to be taken.

A transition of plants’ process technology to a concrete structure also means that complicated pre-

fabrication steps and an elaborate pre-treatment of the substrate in large-volume absorption towers

are not needed anymore. Even complex structures can be constructed quickly and safely.